PROTAPER ULTIMATE SHAPER

One of the goals in preparing canals is to use an economy of instruments, or to fulfill the international clarion cry, “less is more”. To that end, the PTG S1 and S2 files were combined into one, progressively increasing percentage tapered, ProTaper Ultimate super SHAPER. The SHAPER is utilized in an access cavity flooded with NaOCl to dominantly remove restrictive dentin in the coronal and middle one-thirds of canals. Pre-enlargement provides access to the typically more curved and anatomically challenging apical one-third of the same canal. Whereas the PTG S1 and S2 are produced from 1.20mm NiTi wire, the Ultimate SHAPER is produced from 1.00mm NiTi wire to maximize remaining dentin in the body of the canal.

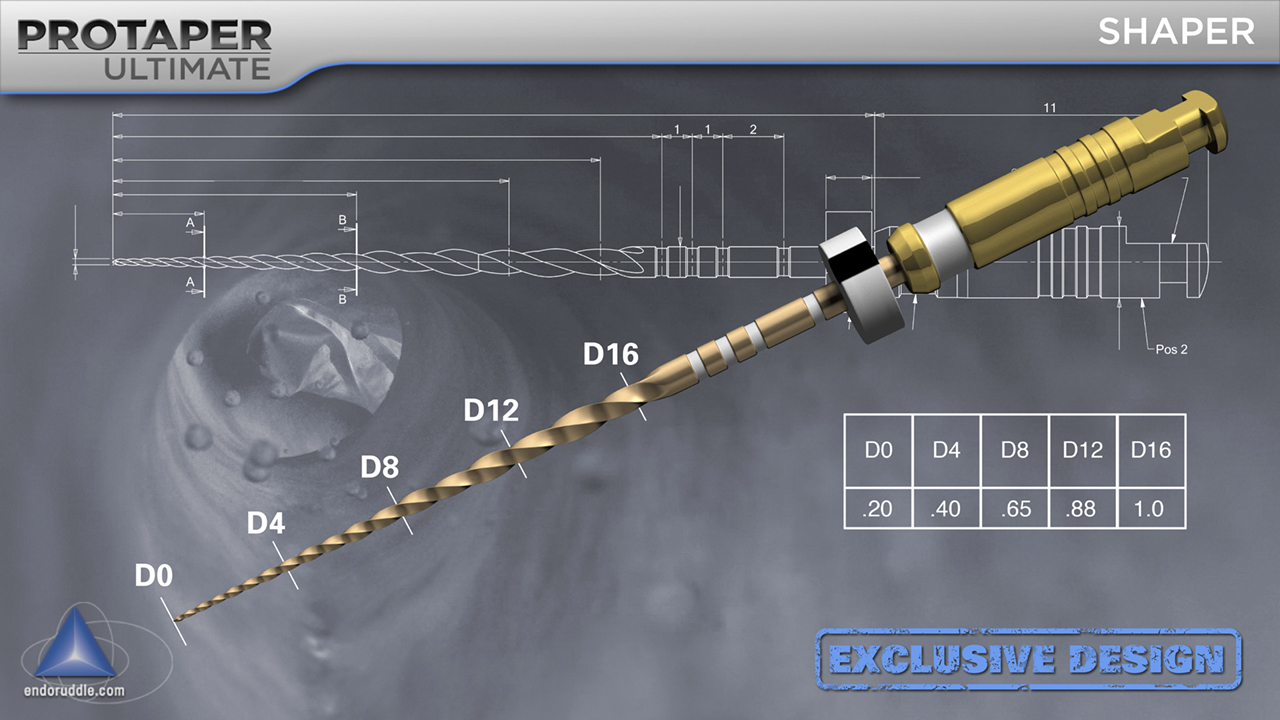

The ProTaper Ultimate SHAPER, with the white silicone stop and identification ring on its handle, has a progressively increasing percentage tapered design over its active portion with cross-sectional diameters at D0, D4, D8 and D16 of 0.20mm, 0.40mm, 0.65mm, and 1.0mm, respectively.

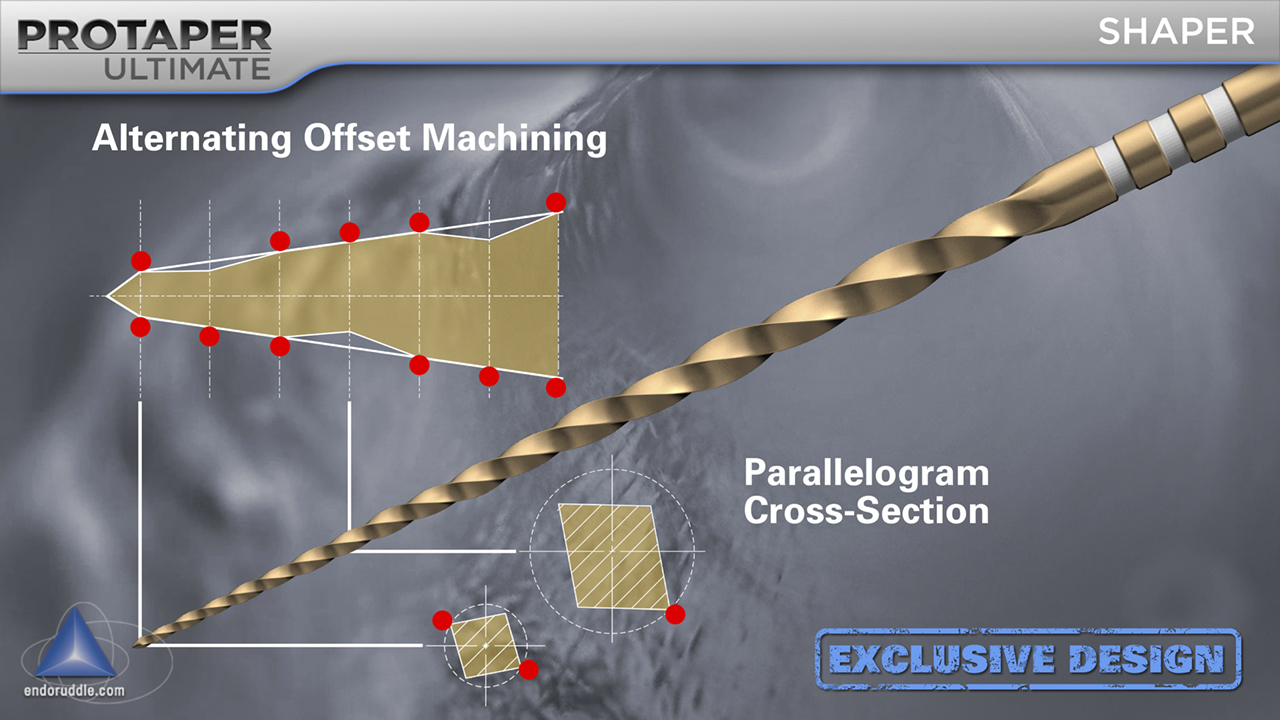

The SHAPER has an ever-changing cross-section that evolves from a rhomboid to a parallelogram along its active portion. This cross-section promotes safety and efficiency as there is less contact between the file and dentin. The Ultimate SHAPER has an additional advantage in that this file is produced by a proprietary Alternating Offset Machining (AOM) method. This machining method limits file engagement. Specifically, the SHAPER will touch the internal walls of a theoretically round canal at two (2) points, then one (1) point, alternating in this manner, along the active portion of the file. AOM serves to increase safety and performance, decrease the screw effect, and provide more internal space to load, auger, and haul debris out of a canal.